The laptop market segment grew over the past year. Due to work-from-home setups, laptop shipments in 2020 hit 216 million units. In 2021, most experts project its growth to 225 million.

Update Nov 16, 2022

The laptop market segment actually beat that 2021 projection by reaching 275 million units sold. However, in 2022 the laptop sales boom of the pandemic era is over with declining sales in 2022 as a result.

The demand increased because people need to become more mobile. We do everything on the go, from contacting thesis helpers or even working an office job. As such, the laptop manufacturing market will grow over the next few years.

As these computers become more common, did you ever wonder how they come into our hands?

The process is complex, but our guide will walk you through it. Keep reading and learn more about the laptop-making process.

Design and Raw Materials

The process starts with the production of a design. Companies spend a lot of money and time researching a single unit. The first figure out the need for a specific product and model a product centering on those needs.

From this plan, the engineers can figure out the necessary materials and equipment. They will finalize the appearance and materials needed for the laptop. After that, they start producing and sourcing their products.

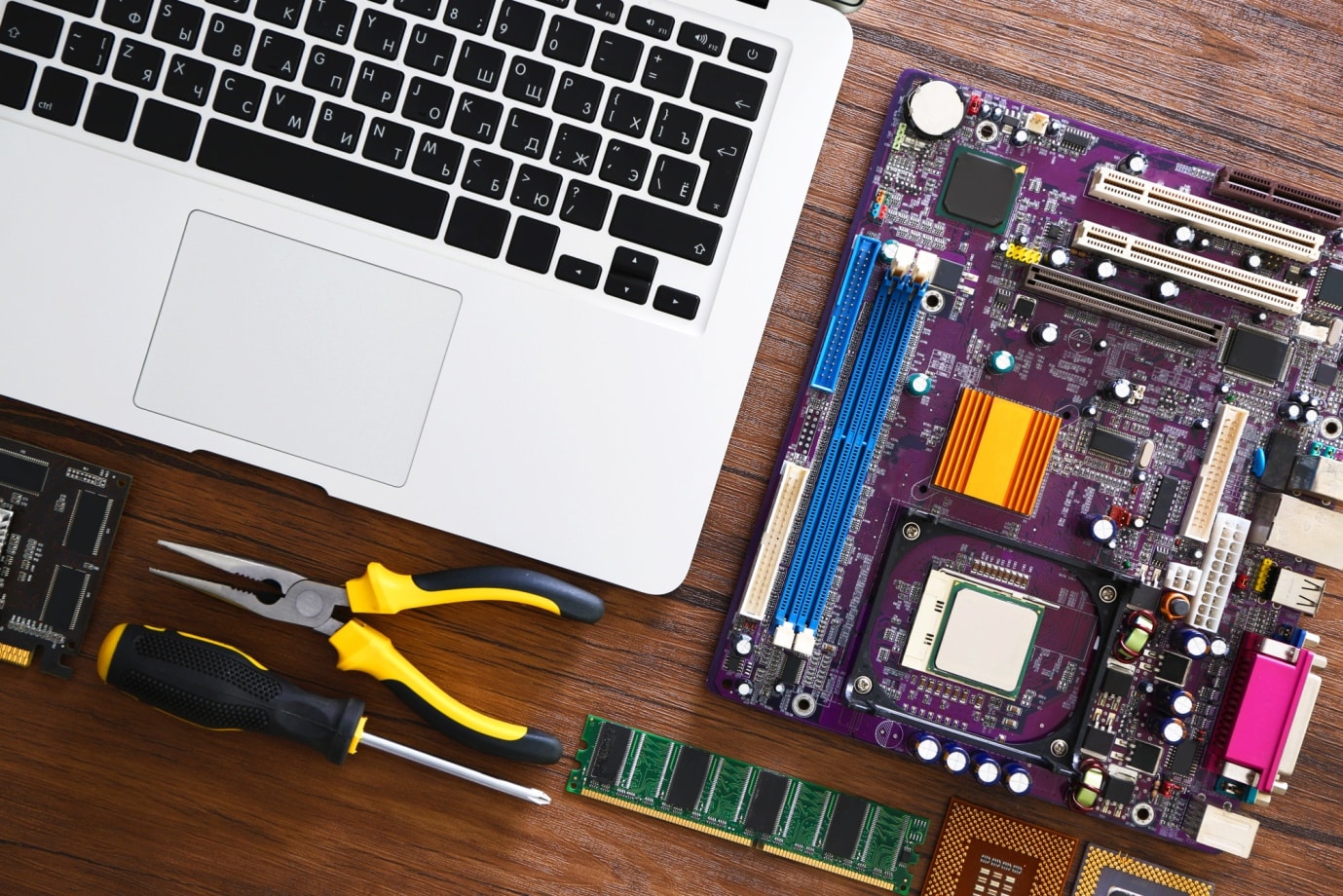

Engineers and product specialists create a detailed design of the laptop. They specify the material, the look, and all the other computer components. Often, they will include the memory, motherboard, and CPU.

These steps are only for laptop design. However, designing the hardware, such as the hard drives and CPU, are another matter. They can either come from other companies or the laptop company.

Motherboards, RAM, flash memory chips, and other components use extensive engineering techniques. It is the reason laptop manufacturing companies do not usually produce these parts in-house.

Gathering of Raw Materials

After the engineers come up with a design, the manufacturer must have the resources to build it. A single laptop contains a tremendous range of materials. These can be both natural and artificial.

A laptop contains gold, ore, glass, steel, carbon, polymers, and other materials. Each can come from many different places before going into a single factory. Laptop manufacturers import most of these components from overseas.

For example, silicon is the most vital ingredient in the CPU. It comes from sand or silicon dioxide, which undergoes a purification process. It is the most crucial step since impurities cause the chips to fail.

After obtaining pure silicon, chipmakers slice the crystals into wafers. These wafers form into electronic circuits containing billions of resistors, transistors, and more. They become the microprocessors and memory chips we know.

Raw material gathering is only a process for a single part. However, laptops contain many other components. More complex steps happen during the manufacturing process.

Building the Components

Factories have different specializations due to the complicated nature of each component. For this reason, each location produces a specific part.

The manufacturing process becomes simpler when taken one step at a time. Here are some steps when making the most popular parts of a computer.

CPU

The CPU requires more than the silicon wafers described above. For example, it also needs metal components.

CPUs use copper because it has less resistance to electrons than other types of metal. It also has less space between the atoms.

The silicon wafer undergoes photolithography. Here, a complex machine uses light to etch an image onto a wafer. Copper fills the etching to form transistors. The process repeats several times to build layers, creating the CPU.

Circuit Boards

The motherboard is the biggest board in a computer. It is a printed circuit board containing slots for other components, like the CPU, GPU, and hard drive. It also connects other peripherals, such as the keyboard, mouse, and monitor.

It handles the primary processing and communication between these components. Without it, the parts cannot interact with each other.

The motherboard and other circuit boards in a computer come from plastic cards. They consist of embedded copper foil patterns. The copper tracks are responsible for transmitting signals between the components.

Display

Various types of laptops use different display types. They look alike, but the processes behind LCD and LED creation will differ.

LCD consists of two sheets of glass. One contains the transistor cells, forming a layer of indium tin oxide. Next is a layer of silicon and transistor parts.

This process repeats to form tiny little cells for each pixel. Remember, there are as many as 1366 x 768 pixels in a laptop screen for cheaper models. High-end variants can have as many as 1920 x 1080 pixels.

LED screens have two parts: the primary display body and a set of controllers. The former has several display panel units made of light-emitting materials. Meanwhile, the host controller organizes and reorganizes video communication signals.

Assembling the Laptop

After completing the components, the creation process is far from putting a laptop on the shelves. All components coming from different sources go into another factory. Here, the laptop manufacturer assembles the parts.

Assembling a computer starts with the specs. Remember the laptop design we mentioned earlier? Workers use it to find the necessary motherboard, CPU, and other components to build a specific model.

The components go into a conveyor belt moving toward technicians. These people are responsible for building the laptops. As they assemble the unit, they scan the serial number of each component.

With the serial number, the manufacturer will always know what’s inside your specific machine. It allows them to offer better technical support when you call tech support. When a certain batch of parts is faulty, they know the units to recall.

Most laptop companies allow you to customize laptop specifications after ordering from their websites, such as www.lenovo.com. For example, you want an Intel Core i9 instead of an i7. In some cases, you want 2 TB of storage instead of the standard 512 GB.

Regardless of your request, your order goes into the manufacturer’s system. A worker pulls the necessary parts and puts them on the conveyor belt.

Software Installation

Laptops usually come with preloaded software. They do it to ensure the laptop user does not have to buy and install an operating system. As a result, these machines are ready to use as soon as you buy them off the shelf.

After the assembly, the laptops go into the software installation area. The manufacturer installs the operating system and other software, like the browser, photo viewer, and more.

Laptop makers can install any custom software at this stage. Sometimes, they also load trial versions of other software. This step also applies when you order additional applications.

Boot-Up and Burn-In

The technicians still have to test the laptops to ensure they are working. They have to track the laptop experience before the units make their way into the stores and customers’ hands. After all, the manufacturer’s reputation is at stake.

They turn on the laptop and perform tests to find faults in both the hardware and software. In a process called a burn-in, the system stays on and runs for an extended time.

A burn-in is a vital part of manufacturing. However, it can also apply to repairs and maintenance.

In this scenario, the laptops run for several hours or days at a time. It is because certain malfunctions may only happen at a specific temperature. For instance, an error might only pop up when the computer warms up.

A faulty device may need more variations in the environment during the testing. It helps find the malfunction when it does not become apparent right away.

However, a brand new laptop does not usually require the same level of testing. A defective component often shows up during the initial stage. It is convenient and helps drive the cost down.

When a technician discovers a problem, they can fix it before the laptop leaves the manufacturing plant. Once the device passes the burn-in test, it proceeds to the next step of the process.

Dispatch

Nowadays, most factory processes are automatic. It includes automated testing. Unlike the performance tests above, factory checks ensure every component is present.

Factory testing is a vital step since some laptops may continue functioning even when they lack all components. However, it makes them flimsy and more likely to break down in the long run. Reputable manufacturers cannot afford these slight mishaps since they care about product quality and consistency.

The laptops have to pass all the tests before qualifying for dispatch. Workers pack them into boxes along with the manual and accessories. The manufacturer ships them into several locations.

Learn More About the Laptop Manufacturing Process

It is hard to imagine it takes this many steps for each finished product. Now you know how much work goes into each unit, you can understand the reason for their price tag.

However, these laptop manufacturing processes are only the beginning of your research. Study what to look for in a laptop since these machines have various specifications and purposes. It ensures you make the most out of your investment for your intended purpose.