We have completed all of the hard work. The part or product design is now finished. For those of us experienced as an engineer, the all familiar “hurry up-to wait” process of submitting CAD files for quote purposes, is soon to begin. Not to mention, the all too common delay as one local manufacturer checks for material inventory and initializes an engineering analysis review, checking for potential problems, is surely next to come. 3D Hubs has taken note of this standard business pain point, and the antidote to such pain-points is here.

Following 3D Hubs founding in 2013, they have had the privilege of producing over 3 million parts, for businesses small and large. Having a keen insight into the needs of the clients they serve, finding a solution for their concerns became a priority. This has led to the creation of a proprietary automated Design for Manufacturing (DfM) analysis tool, featuring Artificial Intelligence software. Now that this application is available to the public, let us cover a few of the tool features and benefits.

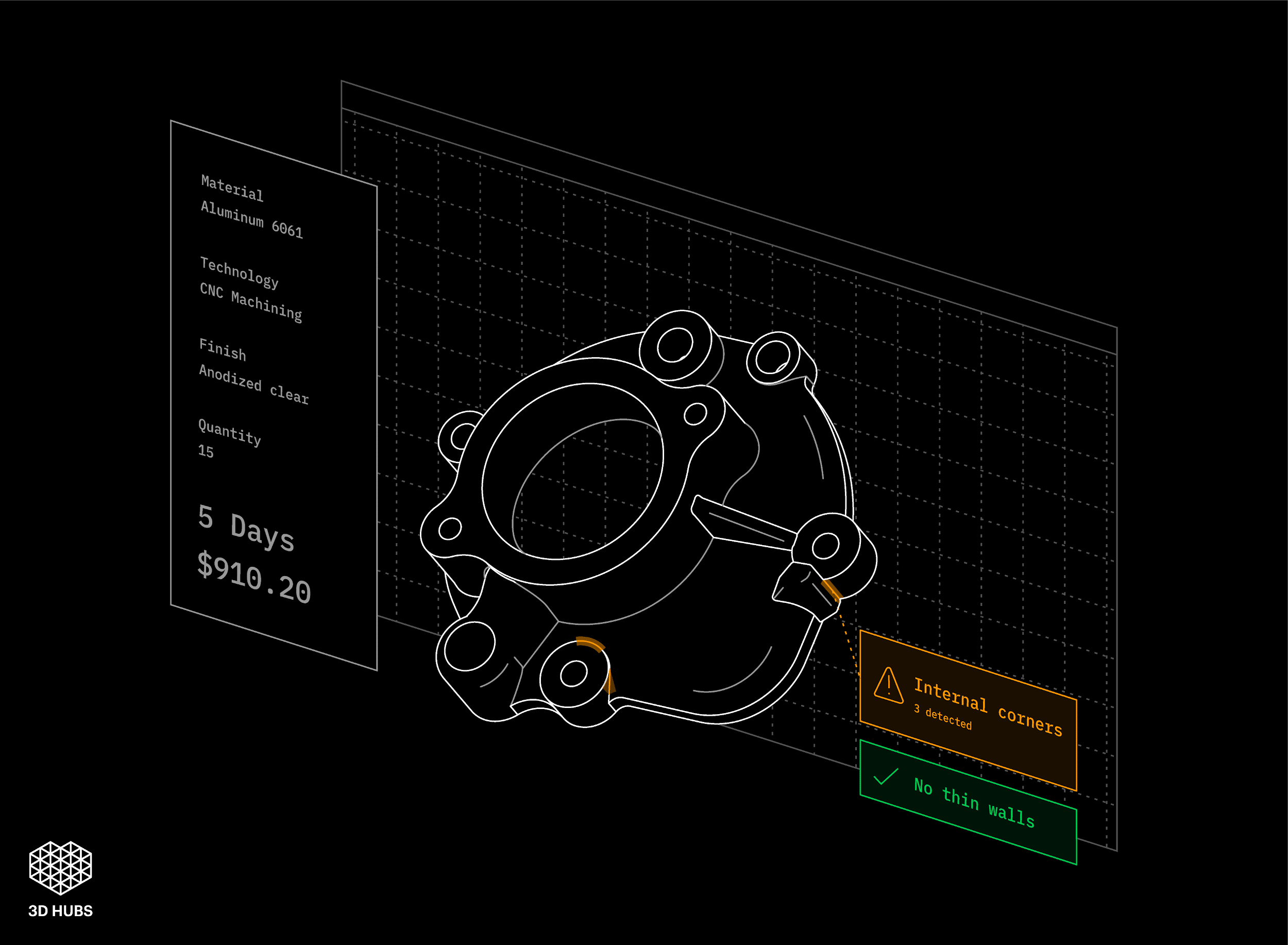

As highlighted above, the customary 3D printing service and CNC machining process, has had its unique ability to “bottle-neck” at just the wrong time. At the offset of the manufacturing activity. With the secured cloud-based technology of the Design for Manufacturing (DfM) analysis tool, speed, efficiency, and cost reduction has been introduced to this stage of the production phase. By simply uploading a CAD design to our impregnable platform in multiple formats (STL, OBJ, STEP, IGES, SLDPRT, 3DM, IPT, SAT, X-T), one will receive an instant price-competitive quote. This speed directly translates to not only a genuine competitive advantage, especially for a smaller business operation, but to savings in bottom-line costs as well. One of the most exciting features seen by both 3D Hubs and customers alike is the A.I. technology this tool supplies. DFM will conduct an analysis prior to production, and uncover any potential issues with the part or product design. This feature is available for 3D printing and CNC machining.

The ability to track your order from the first step of the manufacturing process, through the completion of the finished item, is likewise a feature of this special tool. Not to mention, your accounts payable activities have been simplified by the use of this tool as well. Easily share your quote or invoice to anyone seen as fit. From your colleagues and business partners to a purchasing department. Simply pay for your invoice via the online platform. This is an additional feature many are finding convenient. 3D printing has never been easier, and CNC services has never been so easy and pain-free.

After having completed, in most respects, the hardest part of a product or part design. Avoid the usual issues involved with the subsequent steps in production.