Lasers are ubiquitous in science fiction, functioning as security measures, weapons, data collectors, and analyzers. It’s easy to point to laser usage in dated shows like “Star Trek” and snicker — but it seems sci-fi has enjoyed the last laugh. Lasers have advanced dramatically in recent years, using new techniques and technologies to solve problems across industries. It seems that lasers will be common in the future — seeing as though they are already common today.

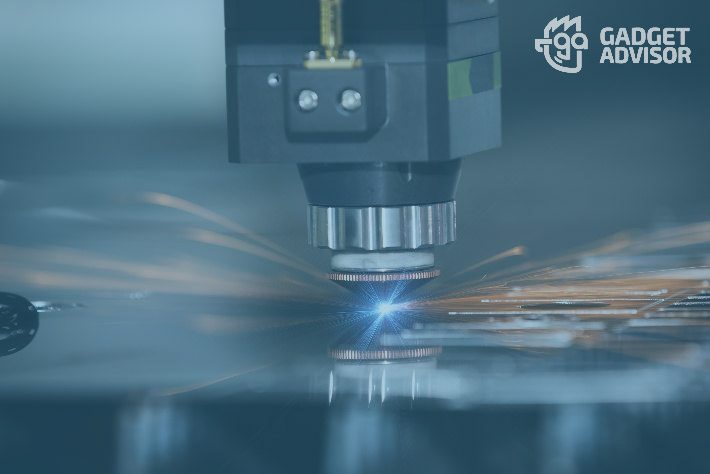

The most practical function of lasers is in materials processing. Originally, lasers were hardly powerful enough to be seen by the naked eye; today, we can produce large and reliable lasers capable of processing a variety of materials in all sorts of ways.

A Brief History of Laser Innovation

While the existence of lasers was first proposed in 1900 by physicist Max Planck — and Einstein first described the process that makes lasers in 1917 — the first real laser (then called a maser) didn’t appear until 1954. Even then, lasers weren’t adapted for use in industry for another decade or so. Laser material processing developed in the late 1960s, when pulsed solid-state lasers were first used for drilling and spot welding and when continuous wave carbon-dioxide lasers were used for cutting and continuous welding.

Swiftly, lasers became indispensable tools for material processing. Laser flame cutting, laser fusion cutting, laser welding, hardening, and cladding evolved in the late 1970s and early ‘80s. However, in those early days, techniques were rudimentary, and not all components were available for use. Initially, lasers lacked beam delivery optics, focusing elements, and gas supply systems, which were not yet optimized for industrial use. For this reason — as well as a dearth of international standards for beam quality and definition — lasers lacked the power and precision we have become accustomed to today. Perhaps more importantly, there existed no or few standardized safety regulations, meaning laser operators undertook serious risks to use these advanced tools.

Still, demand for industrial laser processing systems increased. Slowly, lasers gained diamond-turned copper optics, zinc-selenide transmissive components, and molybdenum-coated focusing mirrors, all of which improved resonator optics, bean delivery, and focusing. Cutting heads also gained automated nozzle distance control and optimized gas flow, both of which made cuts more consistent.

Yet, widespread use of lasers in materials processing was inhibited by one serious factor: Cost. Consumption of gas, electrical power, optics, and spare parts are significant expenses that inhibited the diffusion of lasers into all organizations and fields. Thus, in the 1990s, most laser processor manufacturers began improving solid-state lasers, which require dramatically less maintenance. Using a CO2 slab essentially eliminates the need for gas ventilation and reduces standby electricity needs, but replacing the CO2 entirely with a solid-state fiber decreases loss and further reduces energy consumption. Solid-state lasers have a short longevity — just about 2,000 hours — meaning further innovation was necessary to see wider adoption.

After a shift from rod-shaped to disk-shaped laser activation material and experiments with thermal lenses, laser manufacturers finally transitioned to rare-earth element-doped fiber lasers in the late 2000s. Offering even greater power and control while being virtually maintenance free, fiber lasers are more adaptable to various applications than previous lasers, so one machine can perform dozens of processing techniques. Fiber lasers are simple, robust, and efficient — the perfect combination of qualities for a material processing tool.

How Lasers Will Process the World

Today, laser engraving machines, laser cutters, laser welders, hardeners, and cladders are common equipment in small and large scale material processing, and it only took 40 years of development to make it so. Laser techniques are well-established and, given the power and efficiency of modern laser machines, unlikely to disappear or become obsolete in the coming years.

Experts believe that lasers will continue to evolve, becoming even more accurate and applicable in the realm of materials processing. A laser processing revolution could be on the horizon with diode lasers, which seem to be faster than fiber lasers — but manufacturers must prove that diode lasers are as efficient, reliable, and affordable as fiber lasers, which have set a high bar for laser processing performance. The laser processing tools of the near future should be even more relevant, acquiring applications in new fields, such as additive manufacturing, and expanding applications in vast fields, like welding. Soon enough, lasers could even be integral tools in your home.